Banyuatis Coffee Manufacturing in Buleleng

(Source: http://www.bali-travelnews.com/Batrav/Batrav191/buleleng.htm)

Coffee is a remarkably familiar drink for the Balinese community. Coffee trunk grows well at cool-climate land such as at the territory of Buleleng (North Bali). Most of the territory is good for coffee plantation. Species of coffee cultivated here are Arabica (Coffee arabica) and Robusta (Coffee canephora). From time immemorial Buleleng is the biggest coffee producer in Bali so several inhabitants of South Bali flocked to work there as coffee harvester.

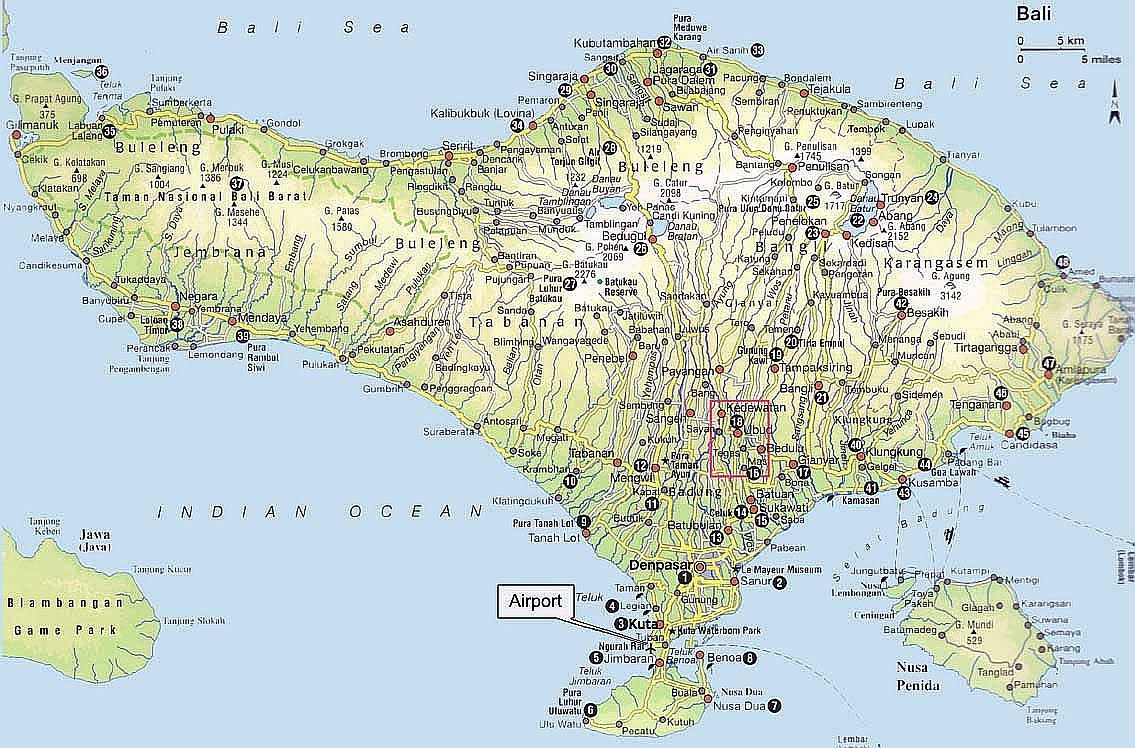

As coffee supplier, either in the form of bean or ready-to-use powder, Buleleng has several enterprises of coffee milling. These enterprises are managed both traditionally and modernly by means of sophisticated and modern machines. One of the moderately well known coffee manufacturing in Buleleng is the Kopi Banyuatis. This company is located at Pemaron Village, precisely on Jalan Singaraja-Seririt. It is close to Baruna Beach, or 2 km east of Lovina Beach.

The Kopi Banyuatis manufacturing was founded by Ketut Englan in 1976. He processes the coffee produced by local farmers from his village, Banyuatis, into the ready-to-use coffee powder. Originally, the company was located at Jalan Diponegoro Singaraja. Then, it was relocated to Pemaron Village to expand its business. Such business is now handled by Gede Harjasa (30) on account of the bustles of Ketut Englan as enterpriser in Buleleng.

The process undergone by the coffee bean into powder begings from the oven, then it is milled and packaged in compliance with the needs. "Our company employs 27 workers consisting of 6 persons in charge on the phase of baking; 3 persons at the milling division to make it into powder and 9 others at packaging division that makes the coffee ready to sell. Administration assistance comes to 2 persons and marketing 6 persons," observed Gede Harjasa.

This company processed 30 tons of coffee monthly. Its products are marketed in different kinds of packages, namely 50g, 100g and 500g. First class coffee consists of the Arabica and Robusta within certain amount of composition. It results in typical distinguished aroma and flavour to Banyuatis coffee, while second world-class coffee is the Arabica mixed with Robusta within certain amount of percentage. It then emanates the aroma and flavour, typically Banyuatis, while for the second class of coffee, the product is blended with the mixture of corn powder.