Article Source: http://EzineArticles.com/?expert=Alun_Evans

More on Alun Evans: http://www.merdekacoffee.com/index.php?88681.4745143056

Bali is known by many names to those who have visited the island. Many Indonesians refer to this slice of paradise as “Pulau Dewa” or “Island of the gods”. Since October 2002 the island has seen a marked downturn in the number of foreign tourists arriving to enjoy the scenic, cultural and religious diversity found here. Hopefully with a peaceful election campaign behind us, Bali will again see tourists returning in numbers.

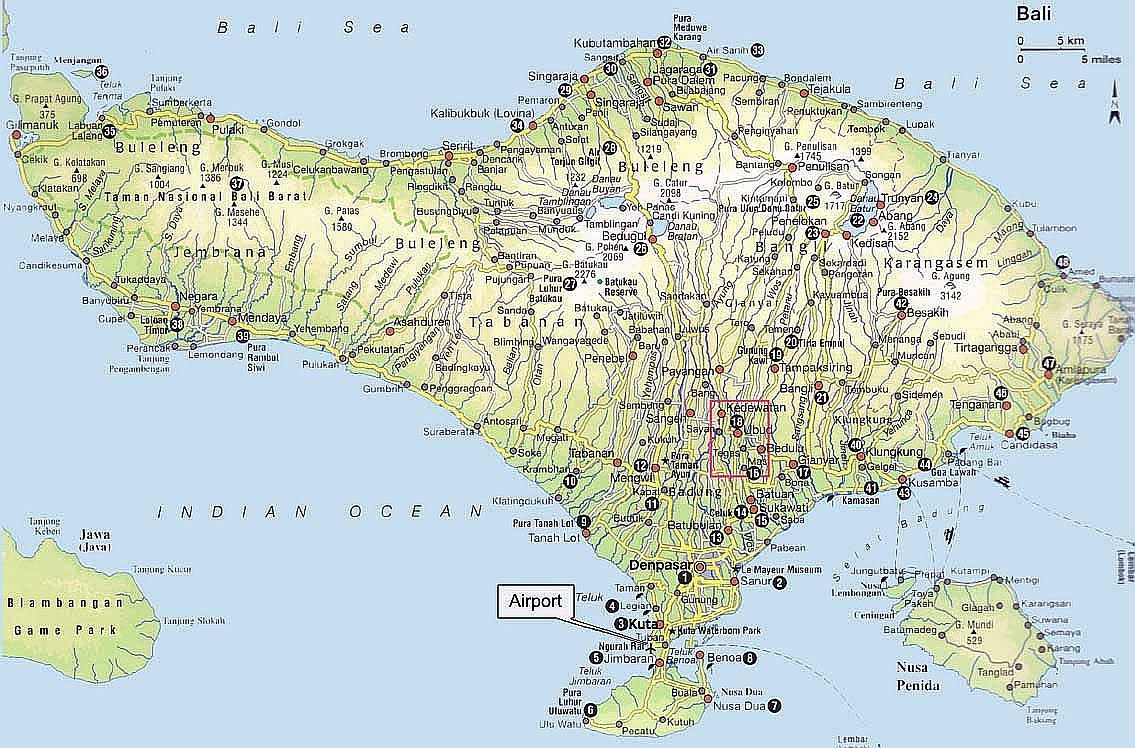

Our visit to Bali in March was not a holiday, but rather a visit to look at the cooperative growing system for Arabica found in the highland areas of central Bali. Traditionally Balinese coffee was of the robusta variety. This is the coffee that many tourists visiting the island experience and love. The origins of Robusta here can be traced back to the beginning of the 20th century or earlier. Commercial Colonial plantations never made an impact in Bali because the Dutch did not get any degree of control over the island until the 1900’s. By this time the big plantations in Java, Sumatra and Sulawesi were already well established. The Robusta in Bali most likely came via traders from Ampenan in Lombok. The growing conditions in Bali are ideal for coffee trees, and small-scale production quickly spread in the cooler, higher altitude areas of the Island.

In recent times, with Robusta prices falling, Arabica has been planted in several areas of the Island. Some of these plantings are in commercial plantations, however the bulk are beans grown by small-holders in a number of villages saddling the volcanic peaks. Our visit was to examine the drying and processing facilities for this mountain grown Bali Arabica.

As in the rest of the coffee world, the small-holders make up the bulk of the growers, but receive little real financial reward for their efforts. Our concern is always to look for a way in which to help these small growers to improve their picking, drying and sorting processes in order for them to be able to market their coffee to the specialty coffee market outside of Indonesia. In most cases the growers are more than happy to listen to ideas on how to improve the finished quality of their product. In Bali the yields from the trees in raw cherries is very good. Most coop growers are uncertified organic- the costs of pesticides against the price for the finished bean do not make sense. The small holders almost universally follow the dry method of processing the beans. This involves laying the fruit out under the sun in large, flat concrete drying pens. The coffee is raked regularly to ensure the drying proceeds at a constant pace. Prior to drying the cooperative removes poor quality cherries- usually berries that are not ripe, have evidence of surface fungal diseases or berries that have been damaged by birds or other pests. After drying and removal of the remaining mucilage, the beans are again sorted. This time beans are sorted based on whether there is evidence of damage by borer, discoloration, black beans or split and broken beans. This is the extent of sorting- there is no screen sizing done by the cooperatives at origin, as normally the beans are on-sold to big producers who then sort further.

We like the early season greens that we saw in the highlands of Bali. The colours and firmness of the bean are good, as was the general quality. Test roasting resulted in us deciding that the dry-processed bean had some characteristics reminiscent of the lower altitude Java Arabica beans. A very mellow, slightly honey-dew taste…..We are looking forward to later in the year when we will be in Bali for the harvest of the bulk of the 2004 crop.

Alun Evans is a New Zealander living and working in sepcialty coffee in Indonesia. He has lived here since 1998 and is working towards a goal of promoting and devloping sustainable coffee in Indonesia.

Article Source: http://EzineArticles.com/?expert=Alun_Evans

More on Alun Evans: http://www.merdekacoffee.com/index.php?88681.4745143056